Injection moulding products feature: Outdoor outlets cover have waterproof, splash proof, and dustproof functions, and are widely used in bathrooms, living rooms, balconies, etc.

The weatherproof plastic shell can protect the socket from outdoor factors such as rain, soil, dust, and snow.

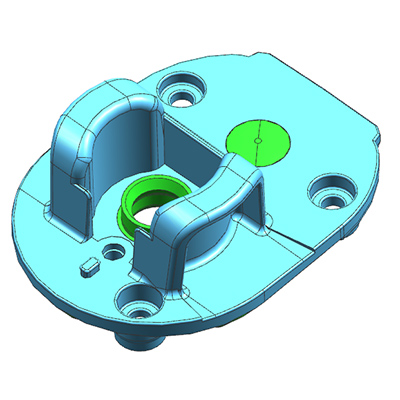

The bottom shell is made of high-quality PC raw materials, with glossy surface, fire protection, and sun protection. The entire bottom shell and surface shell have no sense of breakage, sharp edges, or shrinkage. The technical requirements for this custom plastic injection moulding electrical enclosure are that there must be no defects such as flash, insufficient injection molding, flow lines, air holes, warping deformation, silver lines, cold materials, spray lines, etc. The requirements for mold production are quite high, with high fit, high accuracy, and beautiful appearance without defects.

As injection mold company in China, our advantages

One stop solution for plastic parts

|

Appearance design

| Senior designers with over 10 years of industry experience provide consulting services |

| Product structure | Material, feel, color matching, reasonable evaluation, optimization of product structure, and provision of solutions |

Mold design

| Optimize product structure and mold placement based on product appearance, function, size requirements, appearance requirements, assembly requirements |

| Mold manufacturing | The factory has all the equipment internally and can guarantee fast delivery time |

| Injecton molding | A professional injection molding team with complete single and dual color injection molding machines, auxiliary equipment, and robotic arms |

| Project management | Excellent project engineer, design engineer, proficient in English, able to communicate directly with clients |

| Special experience | Over the past decade, we have focused on exporting injection molds and plastic parts |

Custom injection moulding process

Analyze the product injection moulding process, mold structure, and injection molding manufacturing process to ensure that the mold life meets customer applicable requirements.

Design a complete injection mould structure and machined components, and propose assembly requirements and injection molding process requirements.

Thoroughly analyze the appearance quality defects of plastic parts (such as shrinkage, deformation, etc.) or mold structure problems (such as parting surface, gate, ejection method, etc.) before injection mold manufacturing, and propose corresponding improvement measures.

After the mold drawing complete, provide the mold production schedule to the customer and send weekly processing photos and updated plans to the customer.

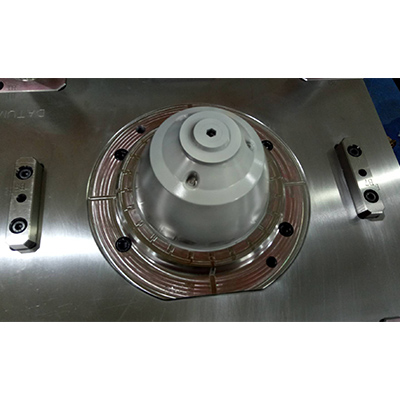

After the mold production is completed, a trial mold is conducted. During the trial mold, 2D product drawings and plastic property tables should be printed to produce plastic parts that meet the 2D product drawings and customer requirements.

Test samples and provide FAI size reports for injection molded products.

After receiving the sample, the customer will propose modifications, and half of them can be transported to the customer after one or two modifications.

Before mold transportation, a trial production, 4-hour or 6-hour trial injection molding process is usually conducted to ensure smooth mold production and provide CPK size reports.

When transporting molds to customers, a complete set of mold document will be provided, including product drawings, mold drawings, part drawings, cooling drawings, injection molding parameters, and maintenance advice manuals.

English

English Deutsch

Deutsch italiano

italiano русский

русский français

français română

română العربية

العربية Español

Español Polska

Polska 日本語

日本語 한국어

한국어

Consulta

Consulta

Llámanos:

Llámanos:  Envíenos un correo electrónico:

Envíenos un correo electrónico:  No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.

No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.